Sand cast aluminum parts series

-

Low pressure cast aluminum series

-

Sand cast aluminum parts series

-

Die cast aluminum parts series

-

Mechanical processing series

-

Sand casting aluminum series

-

Gravity Casting Series

-

Sand cast aluminum parts series

-

Die cast aluminum parts series

-

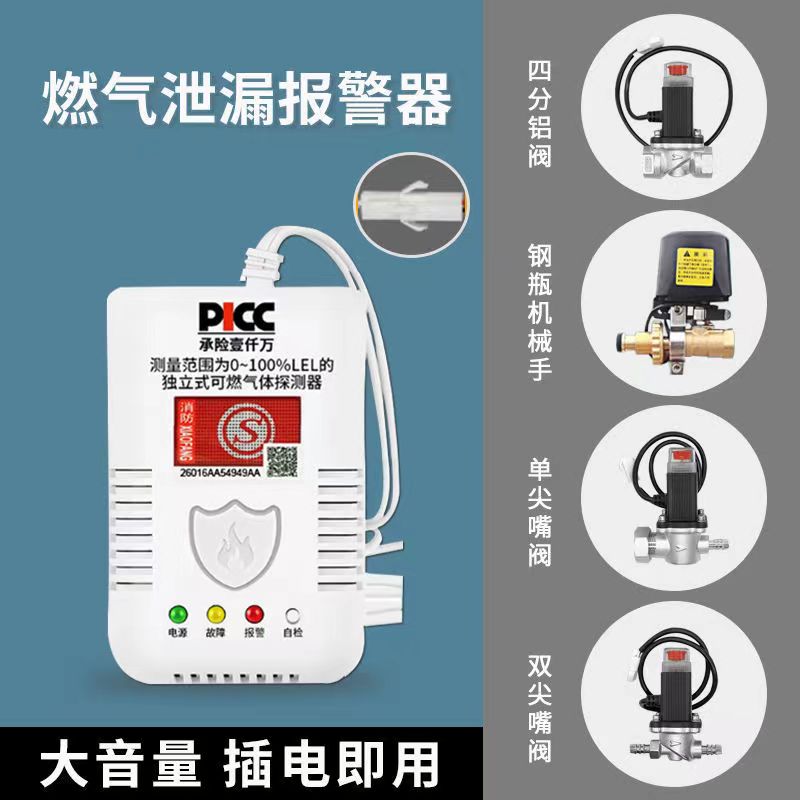

Electromagnetic gas emergency shut-off valve

-

Domestic gas emergency shut-off valve gas leakage

Hot Product

News

2024-05-12

2024-05-12

Sand cast aluminum parts manufacturer - Botou Quanle Metal Products Co., Ltd

To make sand cast aluminum parts, the following points should be achieved:

1: Regular maintenance of sand cast aluminum molds, whether it is metal molds or wooden molds, only good molds can produce good products. Especially when using wooden molds to make sand cast aluminum parts for a long time, the molds are very prone to deformation when they are in a humid state for a long time. Therefore, it is necessary to regularly measure the deformation values of the molds to avoid material waste and extended production cycles due to inaccurate products caused by deformation.

2: Control the production process of sand cast aluminum parts, such as the density of sand material, demolding method, position of pouring mouth, horizontal placement of model, etc. Many factors can affect the later production.

3: The heating and melting method, especially when melting old materials, requires proper material cleaning and temperature control during pouring. High temperatures can cause the appearance of castings to turn black, while low temperatures can result in porosity.

4: Priority should be given to using sand casting technology to produce aluminum castings, which has the advantages of low production cost, simplicity, speed, and high efficiency.

5: Increase the density of large sand compacts. It can significantly reduce the thermal expansion of castings, avoid sparse internal structure of castings, improve the mechanical ability of products, and improve the glossiness and flatness of the surface.

6: Excessive tightness of the sand mold can affect the breathability of the mold. Therefore, reducing its moisture content while minimizing its strength can prevent gas from entering, and sand cast aluminum parts will not produce pores;