Die cast aluminum parts series

-

Low pressure cast aluminum series

-

Sand cast aluminum parts series

-

Die cast aluminum parts series

-

Mechanical processing series

-

Sand casting aluminum series

-

Gravity Casting Series

-

Sand cast aluminum parts series

-

Die cast aluminum parts series

-

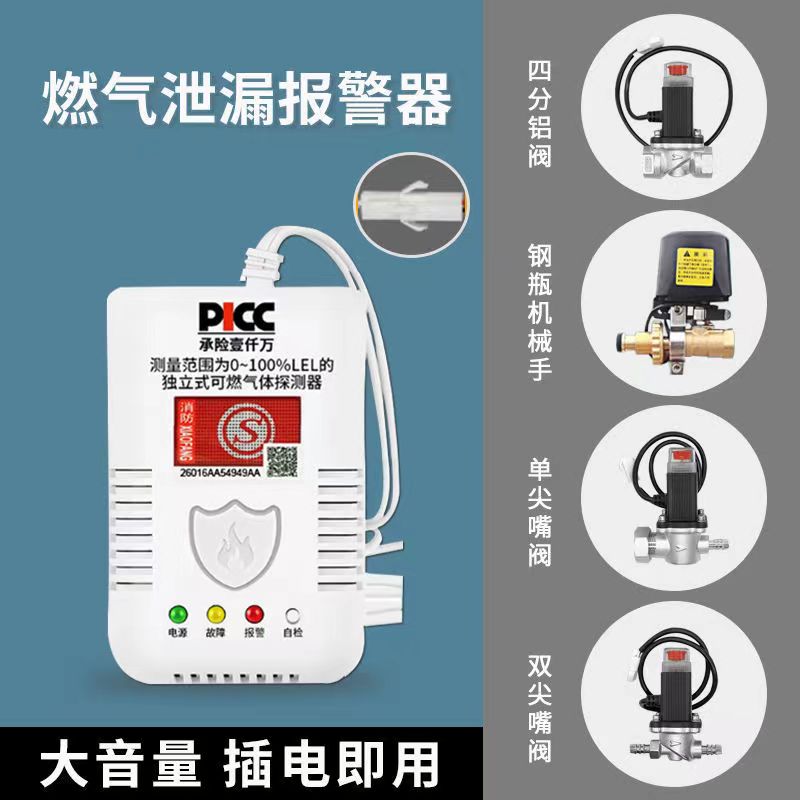

Electromagnetic gas emergency shut-off valve

-

Domestic gas emergency shut-off valve gas leakage

Hot Product

News

2024-05-12

2024-05-12

Die cast aluminum parts manufacturer - Botou Quanle Metal Products Co., Ltd

Die cast parts are a type of pressure cast parts that use a pressure casting mechanical die casting machine with a casting mold installed. The heated liquid metal such as copper, zinc, aluminum, or aluminum alloy is poured into the feeding port of the die casting machine. After being die cast by the die casting machine, copper, zinc, aluminum, or aluminum alloy parts with the shape and size limited by the mold are cast. Such parts are usually called die cast parts. Die-casting parts have different names in different places, such as die-casting parts, pressure castings, die-casting parts, die-casting aluminum, die-casting zinc parts, die-casting copper parts, copper die-casting parts, zinc die-casting parts, aluminum die-casting parts, aluminum die-casting alloy castings, aluminum alloy die-casting parts, etc.

characteristic

Due to the good fluidity and plasticity of metal copper, zinc, aluminum, and aluminum alloys, as well as the fact that casting is done in a pressurized die-casting machine, aluminum die-casting can be made into various complex shapes, as well as high precision and smoothness. This greatly reduces the mechanical processing volume of castings and the casting allowance of metal copper, zinc, aluminum, or aluminum alloys, not only saving electricity and metal materials, but also greatly saving labor costs; Copper, zinc, aluminum, and aluminum alloys have excellent thermal conductivity, small specific gravity, and high processability; As a result, die castings are widely used in various industries such as automobile manufacturing, internal combustion engine production, motorcycle manufacturing, electric motor manufacturing, oil pump manufacturing, transmission machinery manufacturing, precision instruments, landscaping, power construction, and building decoration.

application

Die-casting parts can be manufactured as die-casting automotive parts, die-casting automotive engine parts, die-casting air conditioning parts, die-casting gasoline engine cylinder heads, die-casting valve rocker arms, die-casting valve supports, die-casting power parts, die-casting motor end caps, die-casting pump shells, die-casting building parts, die-casting decorative parts, die-casting guardrail parts, die-casting wheels, and other parts. With the continuous improvement of the development level of domestic manufacturing equipment industry, the equipment level of die-casting machines has also significantly improved, and the types of parts that can be manufactured are constantly expanding. The precision and complexity of die-casting parts have also been greatly improved. We believe that in the near future, die-casting parts will better serve us. Our production and daily life!